Where your waste goes

Recycling

Where does my recycling go?

After your bins have been emptied, the contents are taken to Visy material recovery facility where they are sorted into the various recycling streams. The material recovery facilities either process the recyclables in their own processing plants in Sydney or on-sell the materials to commodity markets.

Why are we not processing all recyclables in Australia?

Australia recycling sector has not the capacity to deal with all the different recyclable materials Australians produce. Inner West Council sends the kerbside recycling to Visy who then own the recycling and determine end markets. Visy can process plastics #1 (PET), #2 (HDPE) and paper/cardboard in their processing plants in Sydney. All other materials from the kerbside recycling bin is send to markets that can process these materials. Steel and aluminium have strong market demand in NSW.

Early 2018 China introduced the National Sword Policy. The policy tightened China’s acceptance on recyclable imports from overseas markets, including Australia. China now requires a cleaner and more processed version of recyclables. Mixed plastic recycling then moved to other Asian countries such as Malaysia which are now tightening their restrictions too. This has impact on how much recycling Australia can send overseas

What is Council doing to strengthen the recycling market?

Councils across the state are working with industry, state and federal government to develop stronger markets for recycling. New markets require cleaner, less contaminated material so it is important that we all continue to recycle and reduce contamination in order to provide the best recycling products.

Australia needs to invest in recycling infrastructure and stimulate market demand for recycled materials. State and Federal Government are working towards a circular economy where recyclables are processed and used domestically. ‘A circular economy is all about valuing our resources, by getting as much use out of products and materials as possible, and reducing the amount of waste we generate.’ (NSW EPA 2019).

The 2025 National Packaging Waste Targets were recently announced by Government:

- 100% of all Australia’s packaging will be reusable, recyclable or compostable by 2025 or earlier

- 70% of Australia’s plastic packaging will be recycled or composted by 2025

- 30% average recycled content will be included across all packaging by 2025

- Problematic and unnecessary single-use plastic packaging will be phased out through design, innovation or introduction of alternatives.

Inner West is working with NSW Treasury, NSW EPA and SSROC to develop a new procurement approach to improve the commercial recycling sector through tendering for recycling services.

What can I do to make my recycling efforts worth it?

1. Avoid plastic

Our main tip is to avoid plastic to reduce the need for recycling.

- Avoid single use plastics, e.g. bring your own container for take away food and drinks.

- Reuse where possible, e.g. reusable coffee cups and shopping bags.

- Reduce packaging, e.g. buy in bulk food stores or choose the not packaged option.

- Contact the companies supplying those plastic products and demand change.

2. Keep recycling

- Check our list of what goes into my recycling bin and you are doing your part for ‘clean’ recycling.

- Download our Inner West Council Waste App to have our A-Z of materials always handy.

- Recycle your drink bottles and cans with Return and Earn, the NSW deposit scheme.

- Keep in mind “if in doubt, leave it out”.

3. Close the Loop

Buy items made out of recycled material. Build the demand for recycled materials to increase the production and availability.

How does the recycling process work?

Inner West Council’s recycling contractor Visy has paper / cardboard and plastic bottle processing plants in Sydney where recyclables are made back into new packaging and drink bottles. All other materials are processed and sold to the commodity markets.

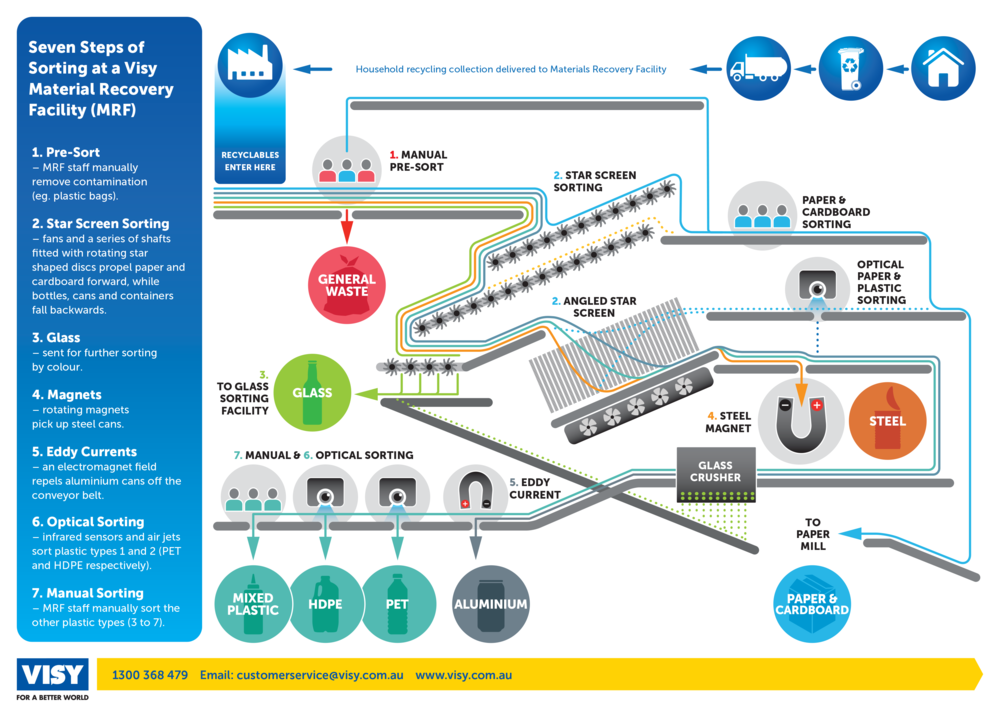

The Infographic below shows the recycling processes

Visy is a recognised leader in the recycling of cardboard paper, plastic, glass, steel and aluminium in Australia, recovering more than 1.8 million tonnes of paper and cardboard, 193,000 tonnes of glass, 91,000 tonnes of plastics and 38,000 tonnes of metals (including aluminium and steel cans) in 2016/2017. For more than a decade, Visy has been teaching the community about why we should all be recycling and how best to go about it. If you would like to learn more about turning recyclables into reusable material, visit: https://www.visy.com.au/recycling/education/

Paper / cardboard - once sorted from other recyclables the paper is compacted and squashed into bales and taken to the Visy paper processing plant where the bales are placed into large mixing pots and stirred in water to produce pulp. The pulp is cleaned and pressed through large rollers to dry, turning it into large paper sheets for paper and packaging.

Plastics #1 (PET) and #2 (HDPE) are manufactured back into plastic bottles at Visy’s processing plant in Sydney.

Plastics #3 to #7 often sent overseas for manufacturing into recycled products.

Aluminium cans are separated using an ‘eddy current' separation unit, which creates a fluctuating magnetic field to induce a magnetic effect in the cans. The cans are then baled and transported to processing plants where they are heated to 700 ° Celsius and made into new cans, saucepans and foil.

Steel cans - A large rolling magnet separates steel cans from the other recyclables. A compacter compresses the steel into large bricks which are sent to companies who shred the steel and melt it to form into new steel products, such as new steel cans, cars, train tracks and planes.

Glass jars are sorted by gravity. Visy sends glass to Recovery Services/OI Penrith who reprocess the glass to be made into new glass products and broken glass for crushing into a sand replacement product for civil works.

Don't place plastic bags in your recycling bin, Visy can't recycle them and they can cause problems in the recycling process. The bags are removed from the recycling stream then sent to landfill. Bags with something inside are removed by hand. The staff can't open the bags to see what is inside - they don't have time and the bags might contain dirty or hazardous items. Empty plastic bags are removed from the recycling stream by mechanical processes; however they can get caught in machinery. Always place recyclables loose in the yellow bin.

For questions about what can be recycled send us an email to rethink.waste@innerwest.nsw.gov.au

Food Organics Garden Organics (FOGO)

After your FOGO bin has been emptied, the contents are taken to the TopSoil Organics commercial composting facility in Forbes. The FOGO material is put through a trommel (a mechanical screening machine used to separate materials), then is shredded, further decontaminated and transferred to a composting platform (called windrows). The windrowed FOGO material is aerated using a windrow turner, and the temperature, moisture and CO2 levels are continuously monitored.

Once the composting process is complete, the FOGO material is tested to ensure it is compliant with EPA and Australian Standards and screened into a range of product sizes prior to sale. The compost and other end products created are used on farms to improve soils and grow more food.

Garbage

After your bins have been emptied, the contents are taken to Veolia's Mechanical and Biological Treatment facility in Woodlawn, which extracts organic content from the waste to produce compost for environmental rehabilitation. Learn more about it on their website.

Park Organics

After the bins have been emptied, the contents are taken to ANL in Greenacre. Learn more about it on their website.

Litter bins

After the litter bins have been emptied, the contents are taken to Veolia's Bioreactor in in Woodlawn. Learn more about it on their website.

Street Sweeping

The contents are taken to Veolia's Mechanical and Biological Treatment facility in Woodlawn, Learn more about it on their website.